- Home

- Featured Projects

- Custom Condensate Splitter Design

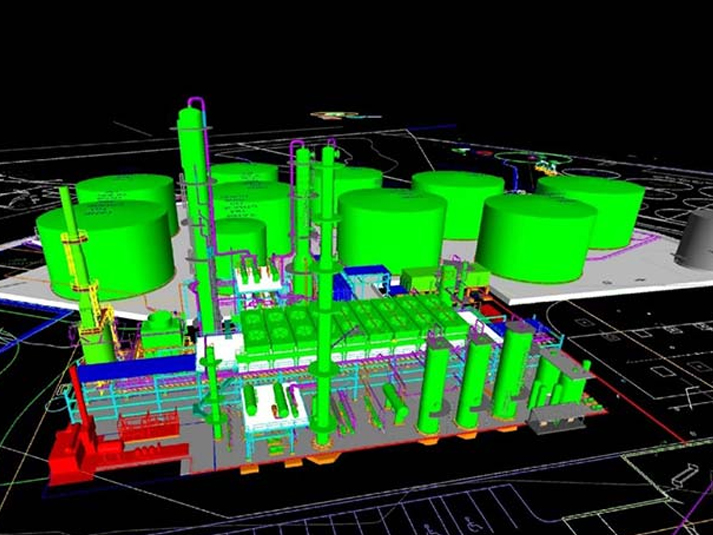

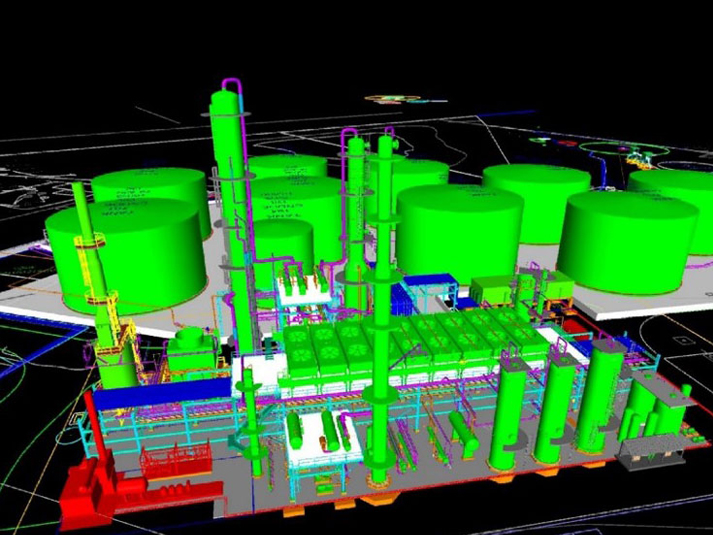

Custom Condensate Splitter Design

After completing the early study phase and the front end engineering design (FEED) phase for a 38,000 barrels per stream day (BPSD) (35,000 BPCD) capacity custom Condensate Splitter located in the Gulf Coast region, KPE was awarded the engineering, procurement, and construction (EPC) contract for the Condensate Splitter.

The scope of the project covers the inside battery limits (ISBL) and the outside battery limit (OSBL), including a 750,000 Barrel tank farm, flare, LPG storage, water treatment facility and associated infrastructure.

Our client requested a design that was economical and compliant with industry regulations. Thanks to a custom design inspired by extensive fractionation experience, we are scheduled to complete the project within a 24 month timeframe. Contact KP Engineering for more information on your project.

Let's talk business