- Home

- Featured Projects

- Tail Gas Treating Unit Design

Tail Gas Treating Unit Design

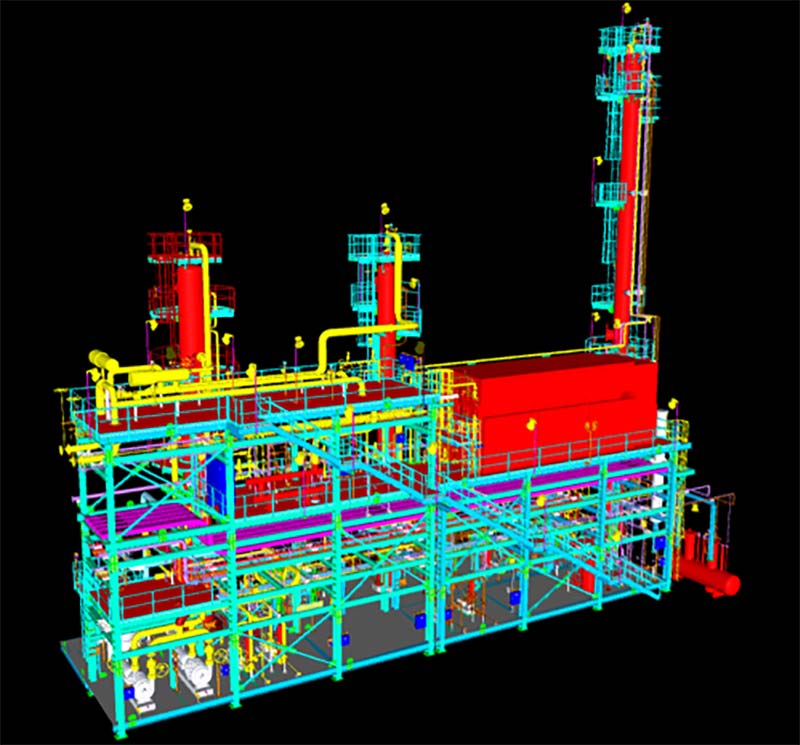

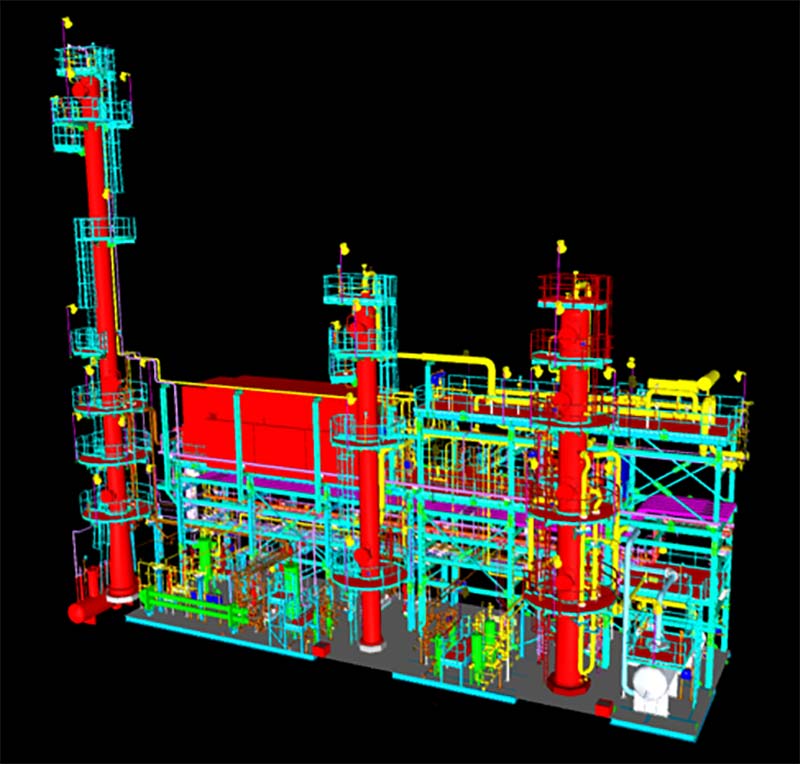

Design and Optimization of a Tail Gas Treating Unit

A Rocky Mountain refiner needed to add a Tail Gas Treating Unit (TGTU) downstream of their existing Sulfur Recovery Unit (SRU) to facilitate additional sulfur removal at increased refinery rates. The client desired an economical 15.8 long tons per day (LTPD).

Client requirements for the tail gas treating unit:

- Capable of meeting strict H2S and sulfur limits for the treated gas

- Be a robust design capable of handling a variable feed composition

- Be able to fit within a relatively tight plot space

Modular TGTU Design Based on Open Art Technology

KPE responded to the challenge by designing a modular TGTU based on open art technology that met all of the client project objectives. The modular design allowed for the majority of fabrication and assembly activities to be conducted in a shop environment and more importantly, shortened the field construction time— an important consideration for harsh winter climates. The design of delivery took six months.

Contact KP Engineering, for More

For more information, contact KP Engineering. Check out past projects and the different markets we serve.

Let's talk business