- Home

- EPC Industries

- Syngas and Hydrogen Plant Design

From syngas to hydrogen, gasification projects have been a point of emphasis for KPE since it's inception.

As your strategic partner, we align our vast experience with your project needs to bring value to your project.

What does this alignment look like for syngas and hydrogen process designs?

- We assess feasibility of the project

- We provide capital and operation cost estimates to inform your investment decisions

- We evaluate options for selecting the optimal technologies

- We execute the most cost-effective, all-encompassing solution for your project

We lead with experience.

For 20+ years, our personnel have conducted a countless number of gasification and feasibility projects (from studies to project execution).

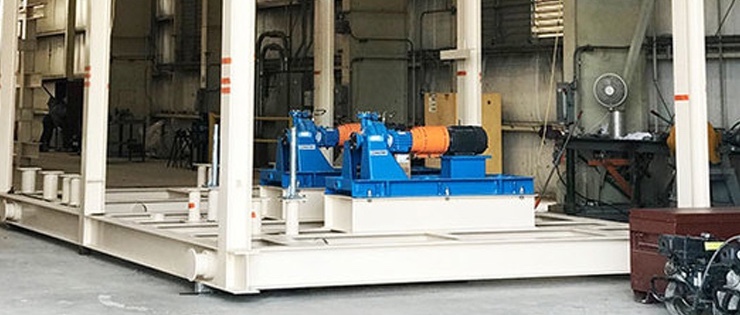

KPE design/supply experience includes two syngas units in Louisiana

- 13 MMSCFD CO Plant

- Syngas Separation Unit

Feasibility studies

- Waste Gasification to FT Liquids – Syngas Cleanup & Shift

- 45 MMSCFD Hydrogen Plant

- 87 MMSCFD Hydrogen Plant

Hydrogen plants

- EPC proposal for 22 MMSCFD H2 plant

- EPC proposal for 25 MMSCFD H2 plant (HTAS SMR technology)

- Budget estimates for 6.2 and 16 MMSCFD plants

- FEL-02 study for fully integrated RDU/H2 plant

KPE personnel experience includes numerous hydrogen and syngas plants

- Experience with Industrial Gas Suppliers and Owners

- Experience with modular and field-erected reformers

- Experience in all U.S. geographical regions

- Global experience with multiple gasification technology providers

We lead with partnerships.

From design to construction, KP Engineering values our relationships with strategic partners. When it comes to designs, having strong relationships with the industry’s leading technology providers enables us to accurately evaluate the best-suited technology for all our customers’ hydrogen, syngas and gasification projects. Key construction companies extend liability coverage and excellent on-site project management. We have spent decades cultivating and fine-tuning these working relationships to save our customers time and money during project development and execution.

We lead by example.

- Hydrogen/Syngas 101:Green Technologies (WEBINAR)

- Created by KP Engineering

- 151 registered attendees

- 17 different countries (from Canada to China)

- Hydrogen and Clean Fuels: an EPC perspective (PODCAST)

- Interviewed by “The Column” industry leading podcast focused on

downstream innovations, created by Hydrocarbon Processing Magazine

- Interviewed by “The Column” industry leading podcast focused on

- Renewable Diesel: A Green Light for Refiners (MARKET REPORT)

- Interviewed by Bloomberg for members-only market outlook report on renewable fuel sector

- KPE Principal Syngas Engineer with 30 years of experience in gasification and syngas related technologies

- Published Author: The Future of Gasification – Cornerstone Magazine – Vol 4, Issue 1

- Recognized panelists at U.S. government forums promoting hydrogen and fuel cells